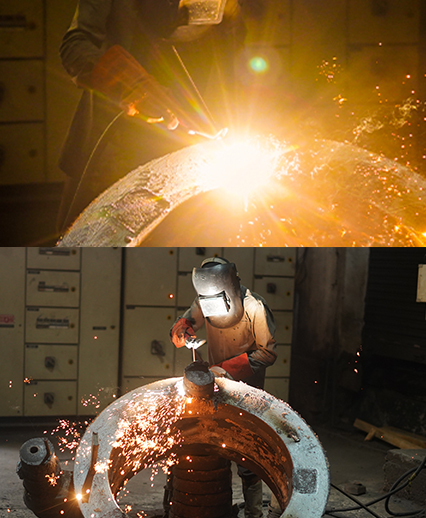

At GWASF, we utilize an advanced combination of

traditional and innovative molding techniques to ensure

defect-free castings that meet the highest standards of

dimensional accuracy and surface finish. Each casting is crafted to withstand

the rigors of extreme environments and operational stresses.

- Casting Methods: We utilize Alphaset and CO2 Molding Processes, meticulously selected based on the alloy type, geometry, and wall thickness to meet the exacting demands of each project.

Our expanded facility houses cutting-edge equipment, optimized for large-scale, complex casting operations.

From precision pattern creation to post-casting fettling, we ensure every casting meets the most stringent quality standards

while delivering efficient, scalable production.

- Pattern Warehouse: Equipped with high-precision pattern storage and management systems, ensuring repeatable accuracy and reducing the risk of dimensional drift during large production runs.

- Heavy Lifting Equipment - Overhead Cranes: 3 MT, 5 MT, 10 MT cranes for handling large, heavy components

- Flood Coating Station & Electric Drying Oven: High-performance coating and drying systems for optimal mold integrity

- Fettling Bay: Dedicated fettling bays for Carbon steel castings and High alloy castings equipped with precision tools to ensure smooth, burr-free finishes.

Our design and engineering processes are seamlessly integrated into the casting development cycle to ensure consistent quality, controlled outcomes, and reliable performance from concept to production. Customer Drawing to Optimized Methoding-

From receipt of customer drawings, our engineering team evaluates design intent and develops optimized methoding to ensure sound castings, improved yield, and compliance with functional and dimensional requirements. Advanced Casting Simulation (Flow-3D Cast)

Casting designs are validated using Flow-3D Cast simulation to analyse mould filling and solidification behaviour. This ensures defect prevention, reduced development risk, and first time-right production.

- Pattern Manufacturing:

We provide service for Patterns making, manufactured with a focus on dimensional accuracy, repeatability, and suitability for consistent production.

- Pattern Scanning & Digital Validation:

Precision pattern scanning is carried out to verify dimensional accuracy and consistency, enabling faster approvals, controlled modifications, and repeatable manufacturing

- Rapid prototyping:

supports early design validation and sampling, enabling timely feedback and design finalisation.

- Quick Turnaround, Faster Time-to-Market:

By integrating engineering, simulation, pattern making, and prototyping under one roof, we ensure controlled development cycles, reduced lead times, and faster market readiness without compromising quality.